Are you looking to level up your drilling game? If you own a drill press, using a drill press vice can make all the difference in your precision and efficiency. A drill press vice is an adjustable clamp that securely holds your material in place, allowing you to drill with greater accuracy and control. Whether you’re a DIY enthusiast tackling home projects or a professional woodworker, using a drill press vice can help you achieve cleaner and more consistent results.

In this blog, we’ll dive into the benefits of using a drill press vice, how to properly install and use one, and some tips and tricks to get the most out of your drilling experience. So, grab your safety glasses and let’s get drilling!

What is a Drill Press Vice?

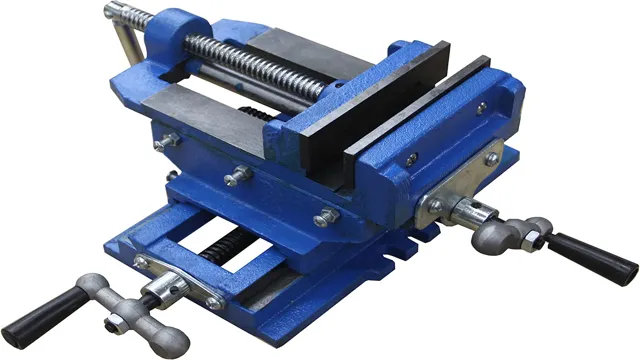

If you’re someone who loves to work with wood or metal, then a drill press vice is an essential tool for you. It is a clamp-like device that is used in conjunction with a drill press to securely hold and position materials during drilling. The drill press vice is designed in a way to fit on top of the table of a drill press and is typically made of cast iron or steel.

So how do you use a drill press vice? First, you need to ensure that your drill press is securely anchored and stable. Then, slide the material you want to drill into the vice and use the adjustable jaws to clamp it down. Make sure the material is positioned correctly and tightened securely before you start drilling.

The vice will ensure that your materials stay in place without any slipping or sliding, resulting in precise and accurate drilling. So, if you want to achieve a high level of accuracy in your drilling, then you must invest in a good quality drill press vice.

Explanation of drill press vice and its uses.

A drill press vice is a type of clamping device designed to hold materials securely in place while drilling. It is specifically made for use with a drill press, which is a machine that drills holes into materials such as wood, metal, or plastic. The vice is usually made from sturdy materials like cast iron or aluminum, and it features adjustable jaws that can be tightened around the material to keep it steady during drilling.

This type of vice is extremely useful for precision drilling applications because it keeps the material firmly in place, reducing the chance of mistakes or errors. Additionally, the drill press vice is typically used in manufacturing, woodworking, and other industrial settings. It is also commonly used by DIY enthusiasts who want to ensure the accuracy of their drilling projects.

So, if you’re looking for a reliable and efficient way to keep your materials from slipping and sliding during drilling, a drill press vice is an indispensable tool.

Installing the Drill Press Vice

If you’re new to using a drill press vice, the installation process may seem daunting. But don’t worry – it’s actually quite simple. First, make sure your drill press is unplugged and the worktable is clean and free of debris.

Then, place the vice on the table in the desired location. Make sure it’s securely fastened to the table using the appropriate bolts, nuts, and washers. Once the vice is securely in place, open the jaws of the vice and insert the workpiece.

Tighten the jaws using the handle to secure the workpiece in place. Make sure the workpiece is stable and secure before starting the drill press. To ensure accuracy, adjust the position of the workpiece before beginning to drill.

With a properly installed drill press vice, you can achieve precise, consistent results every time.

Step by step guide on how to install drill press vice.

If you’re looking to elevate your woodworking game, installing a drill press vice can take your projects to the next level. Here’s a step-by-step guide on how to do it: Start by clearing the workspace around your drill press and making sure it’s unplugged.

Determine which side of the press you want the vice on and mark it with a pencil.

Remove the bolts from the base of the vice and position it on to the marked side of the drill press. Use a marker to highlight where the drill press holes and vice mounting holes line up.

Remove the vice from the drill press and drill pilot holes for the mounting screws.

Securely attach the vice to the drill press with the mounting screws. Finish by tightening all bolts and double-checking the vice is securely attached and aligned properly.

By installing a drill press vice, you’ll have improved accuracy and stability for your projects. Happy woodworking!

Positioning the Workpiece

One of the most important aspects of using a drill press vice is properly positioning the workpiece. First, consider the size and shape of the workpiece, as well as the depth and angle of the holes to be drilled. The vice should be adjusted to firmly hold the workpiece in place without obstructing the drill bit or causing it to shift.

When positioning the workpiece, it’s important to keep your fingers and any loose clothing away from the drill bit and moving parts of the machine. Additionally, make sure the drill bit is properly aligned with the mark on the workpiece, and use a clamp or other holding device to prevent the material from rotating or shifting during drilling. By taking these steps, you can ensure that your drilling is precise, safe, and efficient, and that your workpiece is held securely throughout the process.

How to position the workpiece accurately and safely.

Positioning a workpiece accurately and safely is crucial for any machining process. The workpiece needs to be secured in a vise or a fixture that holds it firmly in place. The workpiece should be positioned in such a way that the cutter or drill can reach all the required surfaces, but not come into contact with any other part of the workpiece or the fixture.

Additionally, the workpiece needs to be positioned in a way that minimizes the risk of injury to the operator. It’s important to wear appropriate personal protective equipment (PPE) and avoid putting your fingers near the cutter or drill. One effective way to make sure you can work on every surface of the workpiece is to break it down into steps and plan out how to approach each step.

This will ensure that you don’t miss any crucial dimensions or features of the workpiece. By taking care when positioning your workpiece, you can ensure that the machining process is accurate, efficient, and safe.

Adjusting the Drill Bit Height

If you’re wondering how to use a drill press vice, one important thing to consider is adjusting the drill bit height. This ensures that your drill bit is at the right level before drilling on your material. First, you need to loosen the bit holder chuck by turning it counterclockwise.

Then, lower the drill bit by adjusting the drill press table until it touches the surface of your material. After that, tighten the bit holder chuck by turning it clockwise, making sure that the bit is secured in place. Now, you can start drilling on your material with precision and accuracy.

Remember to adjust the drill bit height every time you switch to a new material or different thickness. This will help you avoid damaging your material, as well as ensure the longevity of your drill bit. Using a drill press vice can be simple once you know how to properly adjust the drill bit height.

How to adjust the drill bit height with the drill press vice

If you’re working with a drill press, adjusting the drill bit height can be a bit tricky, especially if you’re not familiar with the machine. Fortunately, the drill press vice can help make the process a lot easier. To adjust the drill bit height using the drill press vice, first, make sure the vice jaws are securely holding the workpiece.

Then, use the adjustable stop on the vice to set the depth of your drilling. For more precise adjustments, use the quill feed handle to move the drill bit up or down. Make sure to tighten the quill lock before drilling to prevent any movement.

Remember, accuracy is key when it comes to drill press work, so take your time and adjust carefully. By following these simple steps, you’ll be able to adjust the drill bit height with ease and accuracy, ensuring your drilling project comes out perfectly each and every time.

Safety Precautions

When using a drill press vice, safety must be a top priority. Before using the vice, always ensure that it is securely fastened to your drill press. This will prevent any accidents that could arise from it coming loose during use.

When tightening the vice, make sure to use both hands to avoid any injuries that could occur from a loose grip. It’s also important to take precautions when drilling into materials. Always wear protective gear such as gloves and goggles to shield your hands and eyes from potential explosions or flying debris.

In addition, make sure the material is properly secured in the vice before beginning to drill. This will prevent it from shifting or moving during the drilling process and causing an accident. Keep the drill press area clean and uncluttered, and never attempt to leave the drill press unattended while it is in use.

By following these safety precautions, you can safely and effectively use your drill press vice.

Important safety measures to take when using the drill press vice.

When it comes to using a drill press vice, safety should always be a top priority. To ensure that you are protected from any accidents, it is important to take some basic safety precautions. First and foremost, make sure that your workspace is clean and free from any loose objects or debris that could get caught in the drill press.

Before using the vice, ensure that the drill bit is properly secured and tightened to prevent any wobbling or slipping during use. It’s also important to wear eye protection, as small metal bits or dust can easily fly into your eyes while using the drill press. Additionally, always use the appropriate size and type of vice for the job at hand, and never force your material into the vice.

By taking these safety measures, you can enjoy the convenience and accuracy of a drill press vice while maintaining a safe working environment.

Summary

Using a drill press vice correctly can make all the difference when it comes to precision drilling. A drill press vice securely holds your workpiece in place, allowing for accurate and repeatable drilling. To use a drill press vice, start by cleaning the surface of the drill press table and positioning the vice where you want it to be.

Tighten the vice on the workpiece, making sure it’s centered and secure. Next, adjust the height of the vice to the desired drilling position. When you’re ready to drill, turn on the drill press and slowly lower the bit onto the workpiece.

You can use the vice to adjust the position of the workpiece as needed while drilling. Remember to wear safety goggles and follow all manufacturer’s instructions when using a drill press vice. With a little practice and care, you can get precise and efficient results with your drill press vice every time.

A summary of the key points on using a drill press vice.

If you’re looking to up your drilling game, a drill press vice can be a great addition to your toolkit. This handy device secures your workpiece in place, allowing for more precise drilling. When using a drill press vice, it’s important to make sure it’s properly aligned with the drill bit and drill table.

You’ll also want to ensure that you’re using the right size vice for your workpiece, as well as the appropriate level of clamping force. When drilling, be sure to take your time and work in a smooth, even motion. By following these tips, you can make the most of your drill press vice and achieve accurate, consistent results in your drilling projects.

Conclusion

In conclusion, using a drill press vice is like playing a game of chess, except the pieces are your materials and the drill press is your toolbox. You’ll need to strategically position your materials within the jaws of the vice, clamp them down snugly, and make precise moves with your drill press to achieve the desired result. And just like in chess, success comes through planning, patience, and strategy.

So take your time, think ahead, and let the drill press vice be your trusty ally in your DIY adventures.”

FAQs

What is a drill press vice and what is it used for?

A drill press vice is a clamping device that securely holds a workpiece in place while drilling holes using a drill press.

How do you install a drill press vice onto a drill press?

To install a drill press vice, place it onto the table of the drill press and adjust the jaws to the desired width of the workpiece. Use the locking mechanism to tighten the vice onto the table.

What are the different types of drill press vices available in the market?

Some common types of drill press vices include plain vices, swivel base vices, tilting vices, precision machinist vices, and cross-slide vices.

How do you select the right drill press vice for your project?

Factors to consider when selecting a drill press vice include the size and shape of the workpiece, the required precision, and the drilling angle required.

Can you use a drill press vice for materials other than metals?

Yes, drill press vices can be used for materials such as wood, plastic, and certain composites. However, it is important to adjust the jaws and clamping pressure accordingly.

How do you maintain and clean a drill press vice?

Regularly wipe the vice clean after each use and lubricate the moving parts as needed. If the vice becomes damaged or worn, replace it immediately.

What safety precautions should you take when using a drill press vice?

Always wear appropriate personal protective equipment such as safety goggles and gloves. Avoid loose clothing and tie back long hair. Always secure the workpiece firmly in the vice and never place your fingers near the drill bit while it is in motion.